CPFD Software Presenting at 2024 Global Syngas Technology Council Annual Conference

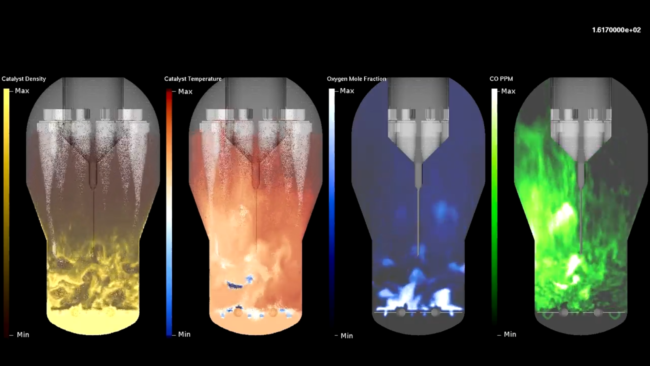

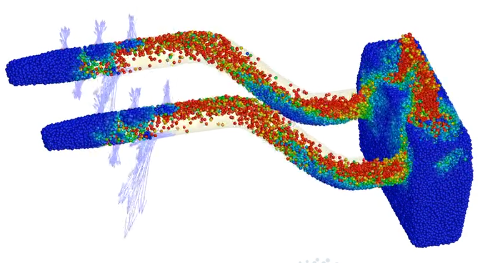

CPFD will be speaking at the 2024 GSTC Annual Conference, October 7-9, 2024. Bryan Tomsula will be giving a joint presentation with Andrew Kramer from Sungas Renewables on “Data-Informed Simulation for Accelerating Biofuels and Alternative Feedstock Utilization”.