CPFD Featured in September 2018 Issue of Hydrocarbon Processing

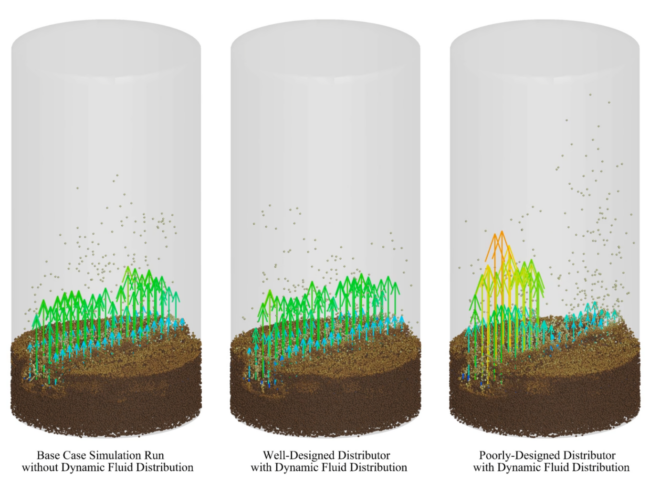

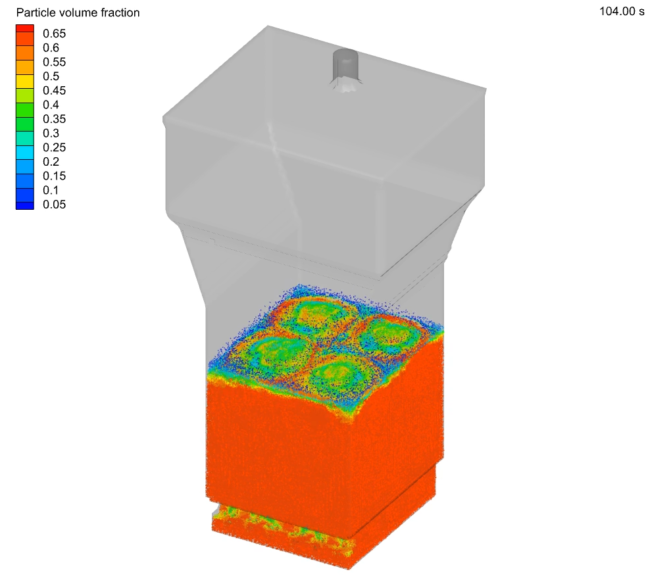

The article entitled “Viva Energy’s Geelong refinery reduces FCCU turnaround risk” is a case study on the application of Barracuda Virtual Reactor® at one of the largest refineries in Australia. Simulations…