About This Video

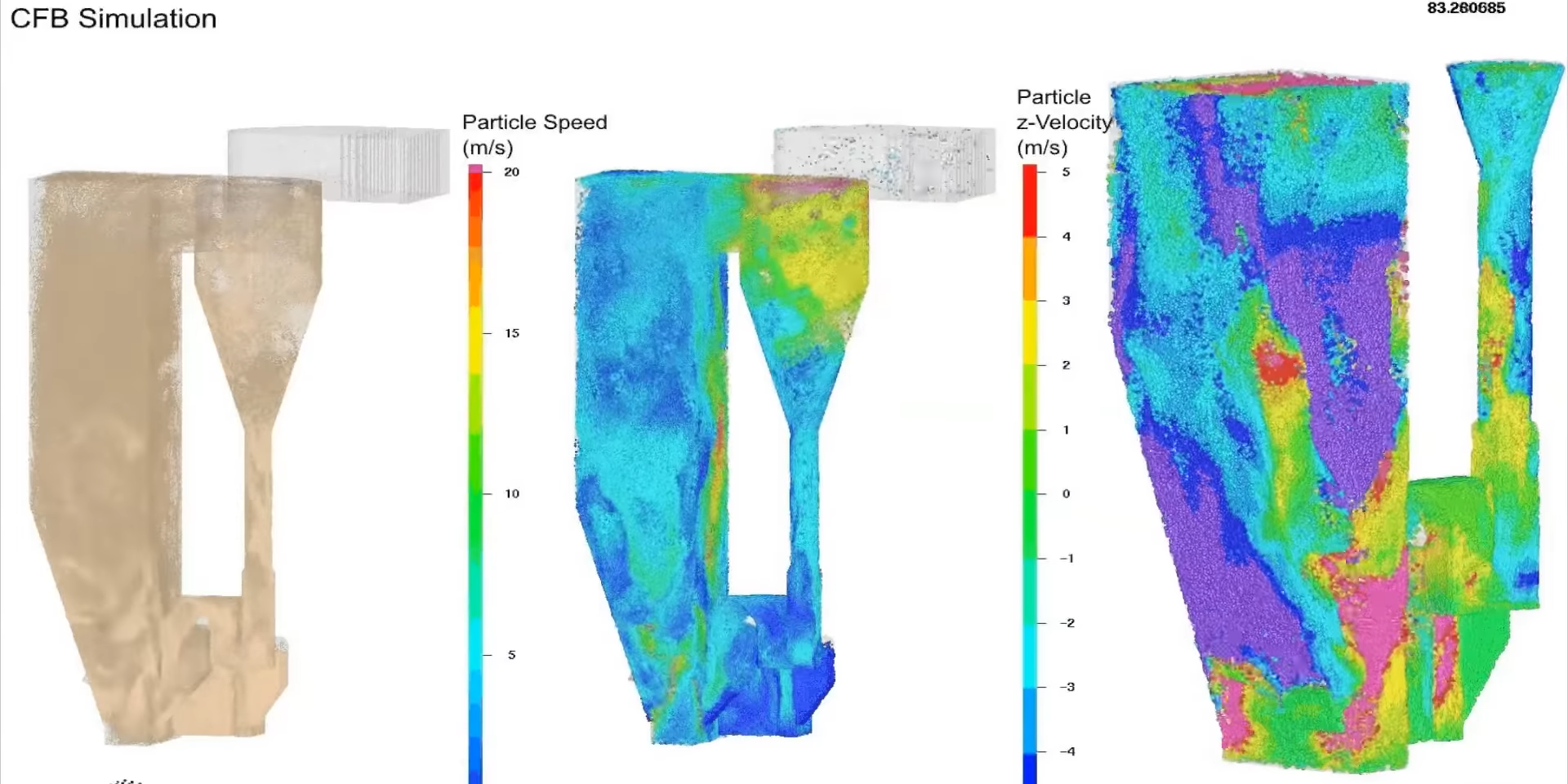

This video shows the model of a full-scale, 3D, circulating fluidized bed (CFB) boiler using Barracuda Virtual Reactor®. This is a simulation of an actual operating unit in Strongoli, Italy, owned by Biomasse Italia SpA. The simulation of the entire CFB loop was performed in order to determine design changes needed to extend the operating cycle of the plant as a whole, which previously had been limited by refractory erosion damage.

Full details on the case can be found in an article published in the International Journal of Chemical Rector Engineering. For more information download the paper or Contact Us.

Visitors from China who are unable to view this view are invited to view it on the Chinese Yanfabu website (中国研发埠学习平台) by clicking here.