About This Video

This Arena-flow simulation models a Jacket Core using the Shell Module, focusing on sand velocity, bulk density, cavity pressure, and fill-time behavior during the core blowing process.

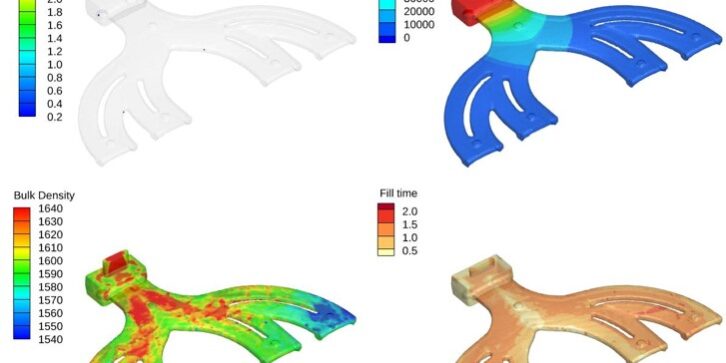

Video layout:

- Left upper: Sand velocity visualization. Regions where sand speed exceeds 0.2 m/s contribute to filling efficiency; slower-moving particles (less than 0.2 m/s) have little impact on additional compaction.

- Left lower: Bulk density distribution as the cavity fills. A target bulk density of 1590 kg/m³ (≈ 60 % compaction) indicates good core quality. Blue areas represent softer, under-compacted regions—potential areas for process improvement.

- Right upper: Cavity pressure field. Rapid pressure drops correspond to effective air movement and strong drag forces, while regions of sustained high pressure may signal stagnant flow or filling issues.

- Right lower: Fill-time map. Each cell is colored by the time it becomes completely filled with sand; a more uniform, lighter color denotes faster, more consistent filling.

Uniform compaction and pressure balance are key indicators of high-quality core production, ensuring consistent density and structural strength throughout the casting core.

To learn more about Arena-flow:

- Visualize sand-to-air dynamics and airflow behavior and analyze efficiency for the system in this video.

- View additional filling details using colored sand, density slices and flux analysis in this video.

- Visit our Sand Cores page.