About This Video

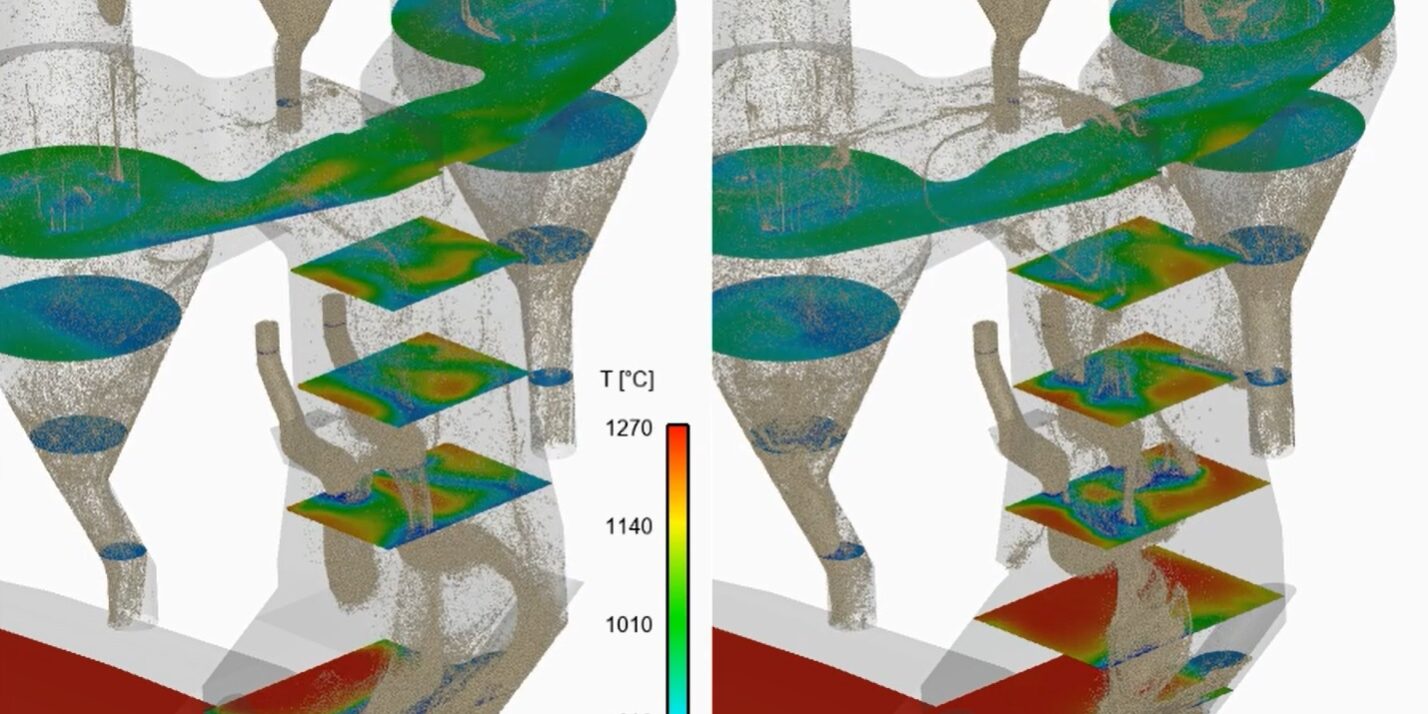

This video, courtesy of aixprocess GmbH, comes from a recent project for a cement plant in Europe where the end client suffered from high preheater exit gas temperatures. Rather than simply modifying the top stage cyclones to address the local thermal concern, a more holistic analysis also detected massive meal dropout from the meal box in the kiln riser to the bottom stage cyclone, which was caused by an undesirable local gas-particle flow behavior. Ultimately this was determined to also be the root cause for the elevated preheater exit temperatures. After performing a digital twin-based engineering analysis, aixprocess developed a plant-specific and low budget modification, which could be implemented quickly during an already planned shutdown.