Challenge

Viva Energy Australia’s Geelong Refinery encountered a performance issue in their fluidized catalytic cracking unit (FCCU), which forced the refinery to reduce throughput, costing tens of thousands of dollars per day.

Solution

Virtual Reactor was used to pinpoint the root cause of the problem. Informed virtual testing of changes then identified and confirmed the viability of a straight-forward solution prior to implementation during a scheduled turnaround.

Outcome

After startup the refinery confirmed a 75% reduction in panel operator intervention and a 4% increase in maximum throughput.

“This project delivered an excellent outcome, giving us confidence that specific hardware changes would restore the operation of our Cracker to the level we expect – which it did,” said Thys Heyns, General Manager of Refining at Viva Energy. “Our team’s collaborative approach brought together CPFD’s expertise and our refinery knowledge. I regard the use of CPFD as a key step in the digitisation of our refinery activities, and it is great to see this project having an impact on the way other refineries are operated around the world.”

Learn More

- Read about it in this article published in Hydrocarbon Processing

- Hear the Geelong team tell their story in this webinar recorded based on our joint presentation at the Asian Refining Technology Conference (ARTC)

- The project was Highly Commended at the 2019 IChemE Global Awards

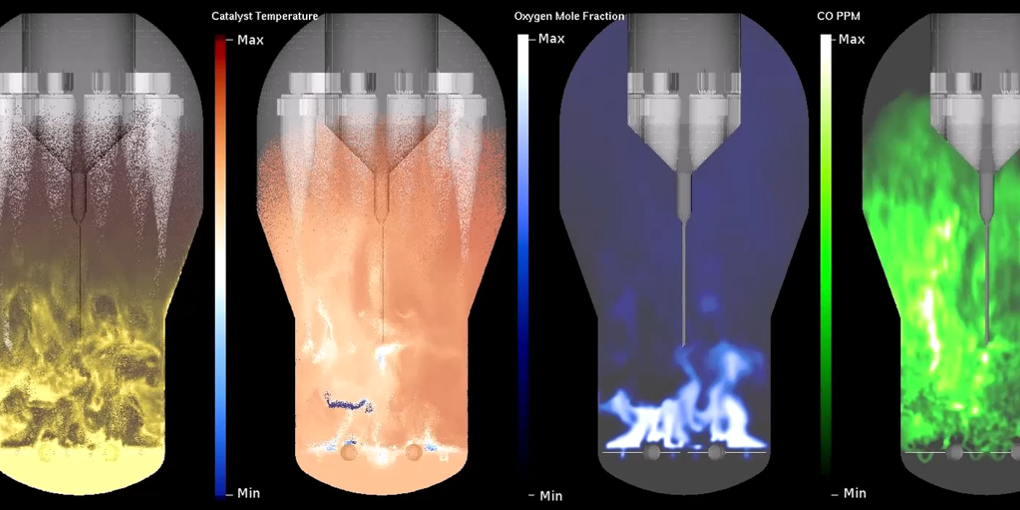

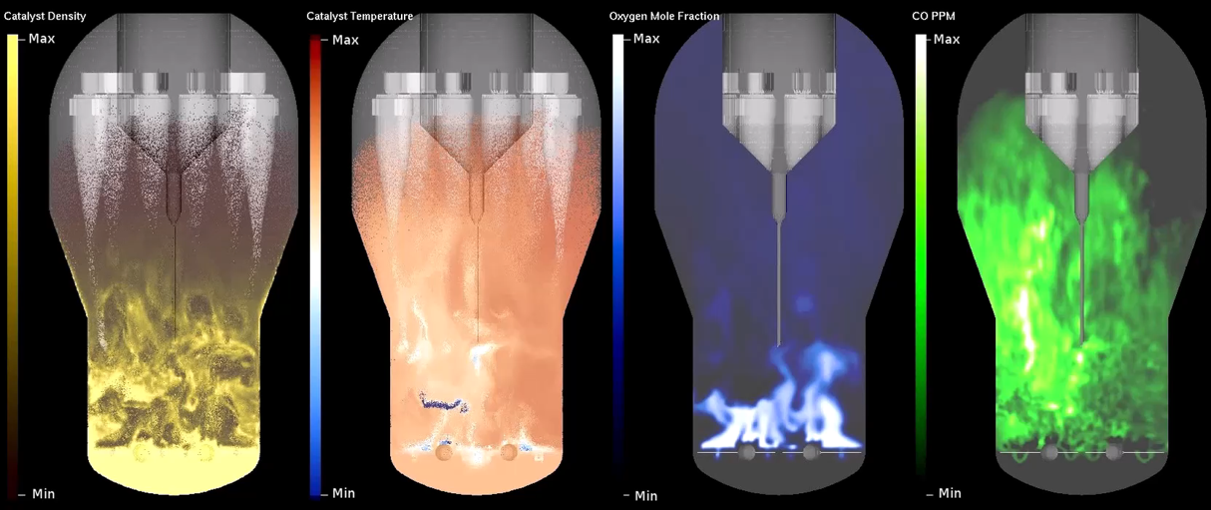

- See inside the regenerator via Virtual Reactor simulation

- Visit our FCC Resources page for more about CPFD’s involvement with refining applications