Application Model Overview

Circulating fluidized bed combustors (CFBCs) are a widely adopted combustion technology offering enhanced fuel flexibility, efficient heat transfer, and reduced pollutant emissions compared to traditional boilers. Leveraging a riser-based design, CFBCs promote excellent mixing of fuel and air, enabling combustion at lower temperatures and reducing NOₓ and SOₓ formation. The recirculation of particles through cyclones and loop seals creates a continuous, stable combustion loop that can accommodate a broad range of feedstocks, including low-grade coals, biomass, and waste materials.

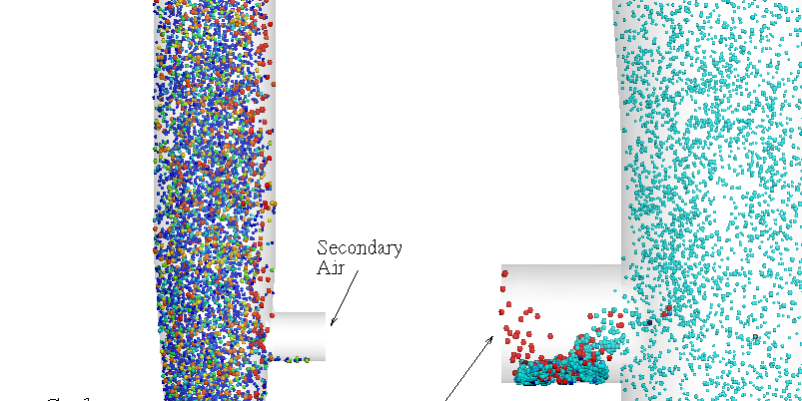

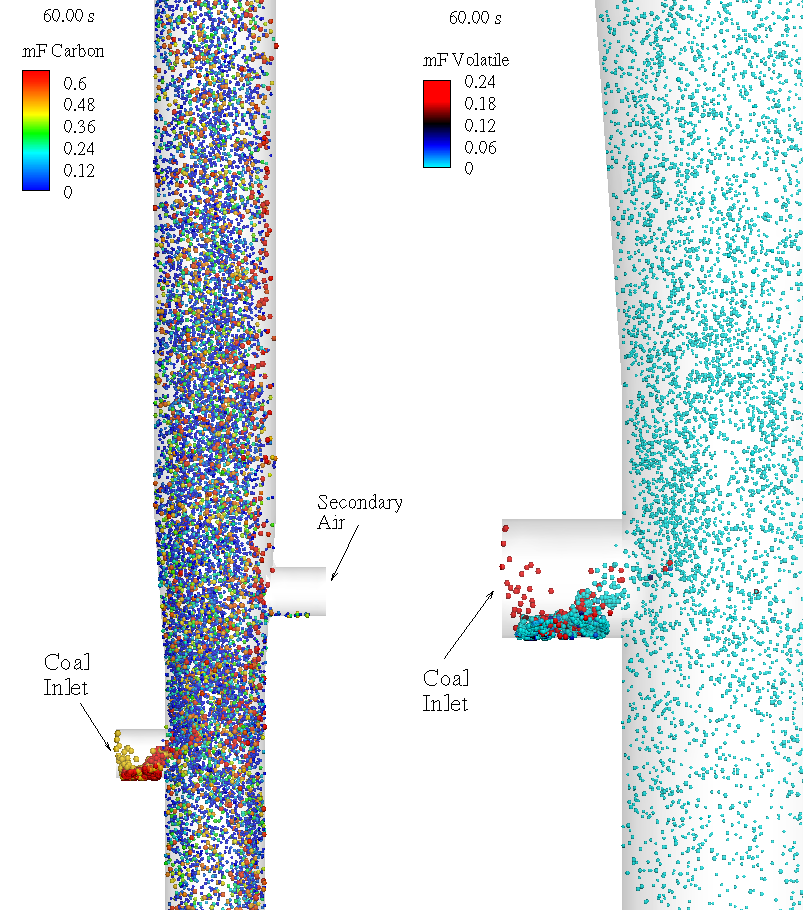

This application model simulates the riser section of a 50 kW lab-scale CFB combustor, as described by Wu et al. (2017), using Barracuda Virtual Reactor. The model incorporates compressible flow with volumetric reaction chemistry and captures the dense, transition, and dilute zones of the riser. Reactions involving volatile species released from bituminous coal—including CO, CH₄, H₂, SO₂, and NO—are modeled using a detailed kinetic mechanism comprising both homogeneous and heterogeneous pathways.

The simulation tracks fluidization behavior, gas-phase species evolution, and thermal profiles throughout the riser, providing insights into combustion efficiency and emissions characteristics. Comparisons with experimental data validate the model, showing strong agreement in predicted outlet mole fractions and riser temperature profiles. This digital twin of a CFBC riser serves as a powerful tool for studying combustion dynamics, optimizing operating conditions, and advancing clean energy applications based on fluidized bed technologies.