Application Model Overview

Modern cement production relies on highly efficient preheater–precalciner systems to maximize heat recovery, reduce fuel consumption, and enable alternative-fuel co-processing. Within this system, the calciner plays a central role: it performs 90–95% of limestone calcination (CaCO₃ → CaO + CO₂), drives the thermal load of the process, and significantly influences plant efficiency, emissions, and clinker quality. Because calcination alone contributes roughly 5% of global fossil CO₂ emissions, advanced modeling of this unit is critical for improving sustainability and operational performance.

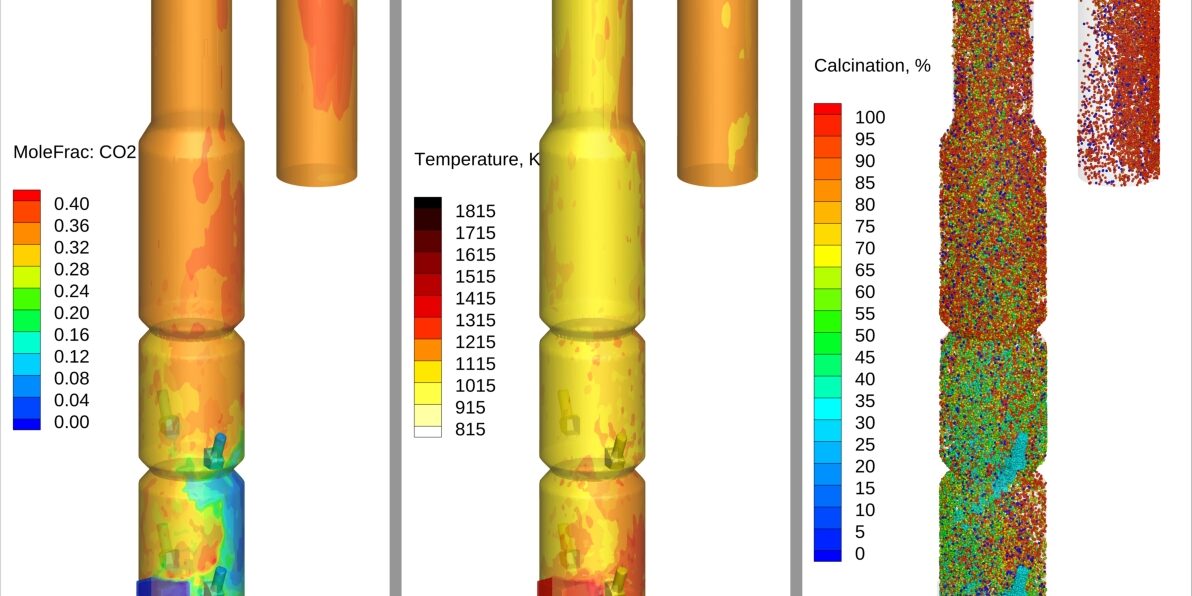

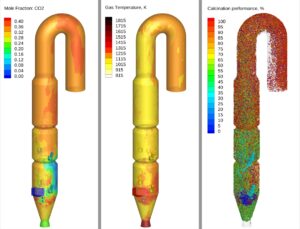

This application model uses Barracuda Virtual Reactor to simulate an industrial-scale cement calciner based on the work of Zhu et al. (2024). The model captures the coupled gas–solid hydrodynamics, coal combustion, devolatilization, and limestone calcination within a compressible, reacting flow environment. Key process features—kiln exhaust injection, tertiary-air staging, multi-level raw meal feeding, coal pneumatic injection, and the riser-to-cyclone transition—are all included to reflect realistic industrial behavior.

A comprehensive chemistry package combines volume-averaged gas reactions, heterogeneous particle reactions, and discrete kinetics for calcination, coke oxidation, and volatile release. Custom Excel tools included with the model help estimate volatile gas compositions and char distributions from coal ultimate/proximate analysis.

Model predictions show good agreement with plant data, accurately reproducing outlet gas temperatures and raw meal calcination levels reported in Zhu et al. (2024). Visualizations highlight key internal trends, including oxygen depletion, CO₂ generation, NOₓ formation/reduction pathways, particle heating, and progressive calcination along the riser.

This application model provides a ready-to-use, literature-based reference for engineers and plant operators studying calciners for troubleshooting, alternative-fuel co-processing studies, and evaluating carbon-capture-ready designs using Barracuda Virtual Reactor.