Application Model Overview

Molten metal bubble column reactors (MMBCRs) are a promising technology for clean hydrogen production and carbon capture. By injecting methane into molten metals like iron or tin, hydrogen can be produced via pyrolysis with minimal CO₂ emissions. In these systems, bubbles act as microreactors where CH₄ decomposes, and the size, shape, and motion of each bubble can significantly impact reactor efficiency.

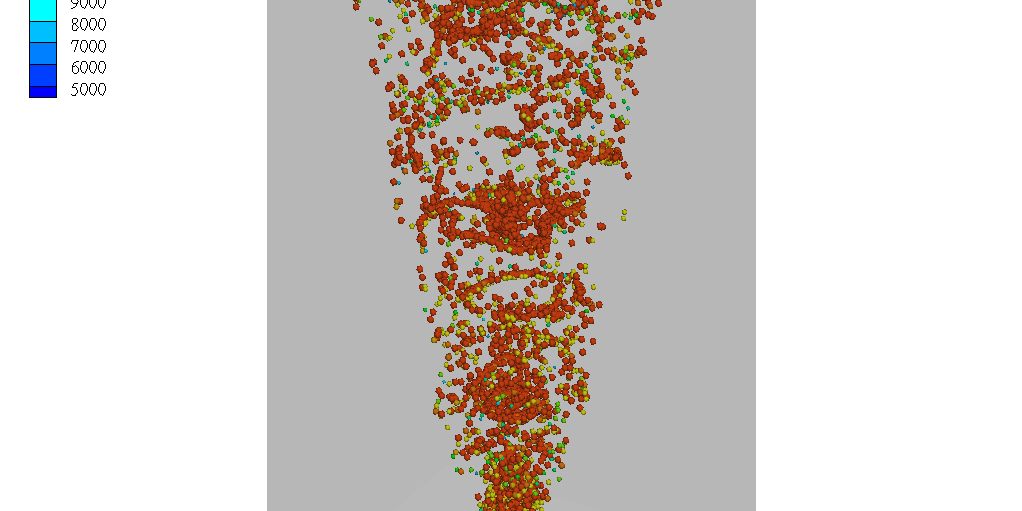

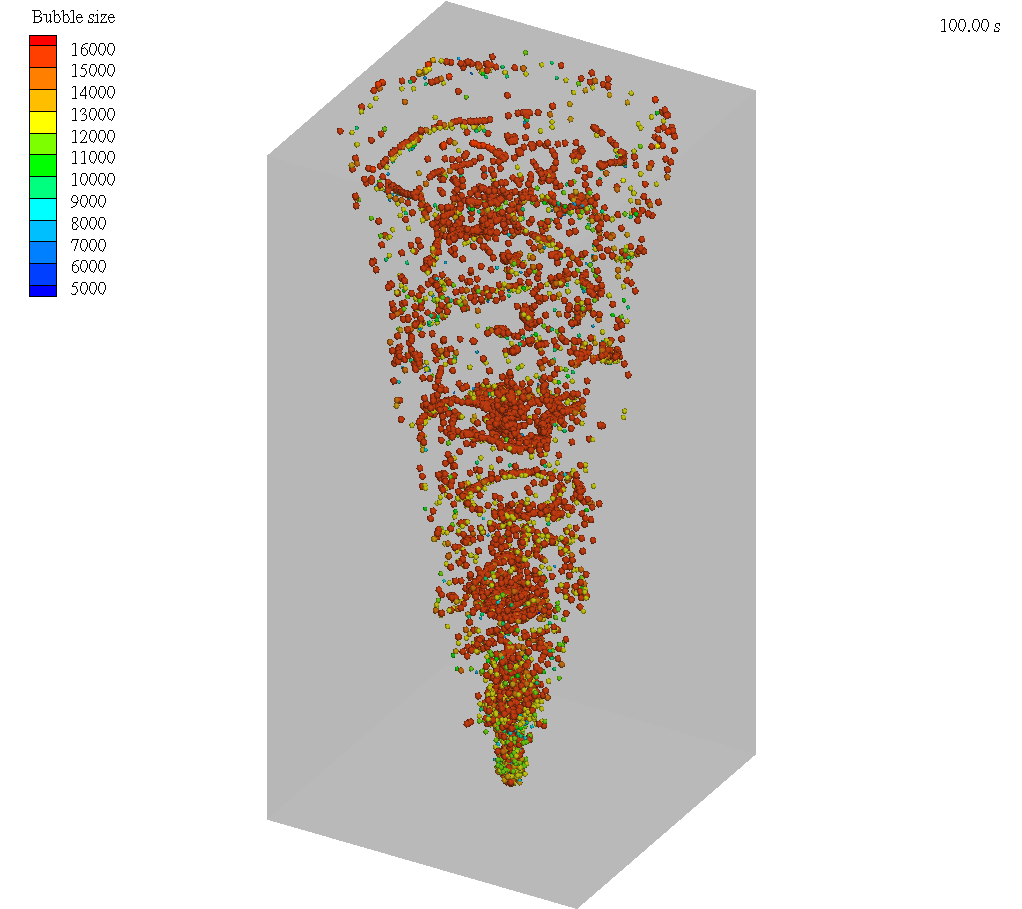

This application model uses Barracuda Virtual Reactor to simulate argon bubbles rising through molten iron in a laboratory-scale MMBCR. While chemical reactions are excluded in this study, the simulation captures detailed bubble behavior—tracking coalescence, breakup, and diameter evolution—as a foundation for modeling more complex reactive systems.

With its ability to simulate multiphase flow involving compressible bubbles in an incompressible medium, Barracuda provides a powerful tool for analyzing bubble dynamics, supporting research and development toward scalable molten metal reactors for clean energy applications.

Additional Resources

-

- Model download and instructions

- Post-processing instructions

- Visualize the Ar bubbles rising, coalescing, and breaking up in the reactor

- Irons, G. A., & Guthrie, R. I. L. (1978). Bubble formation at nozzles in pig iron. Metallurgical Transactions B, 9, 101-110.

- SANO, M., & MORI, K. (1980). Size of bubbles in energetic gas injection into liquid metal. Transactions of the Iron and Steel Institute of Japan, 20(10), 675-681.

- Ngo, S. I., Lim, Y. I., Kwon, H. M., & Lee, U. D. (2023). Hydrodynamics of molten-metal bubble columns in the near-bubbling field using volume of fluid computational fluid dynamics. Chemical Engineering Journal, 454, 140073.