Also available on YouTube.

About This Presentation

Presented by

Martin Weng, aixprocess at the 2022 Barracuda Virtual Reactor Users’ Conference.

Summary

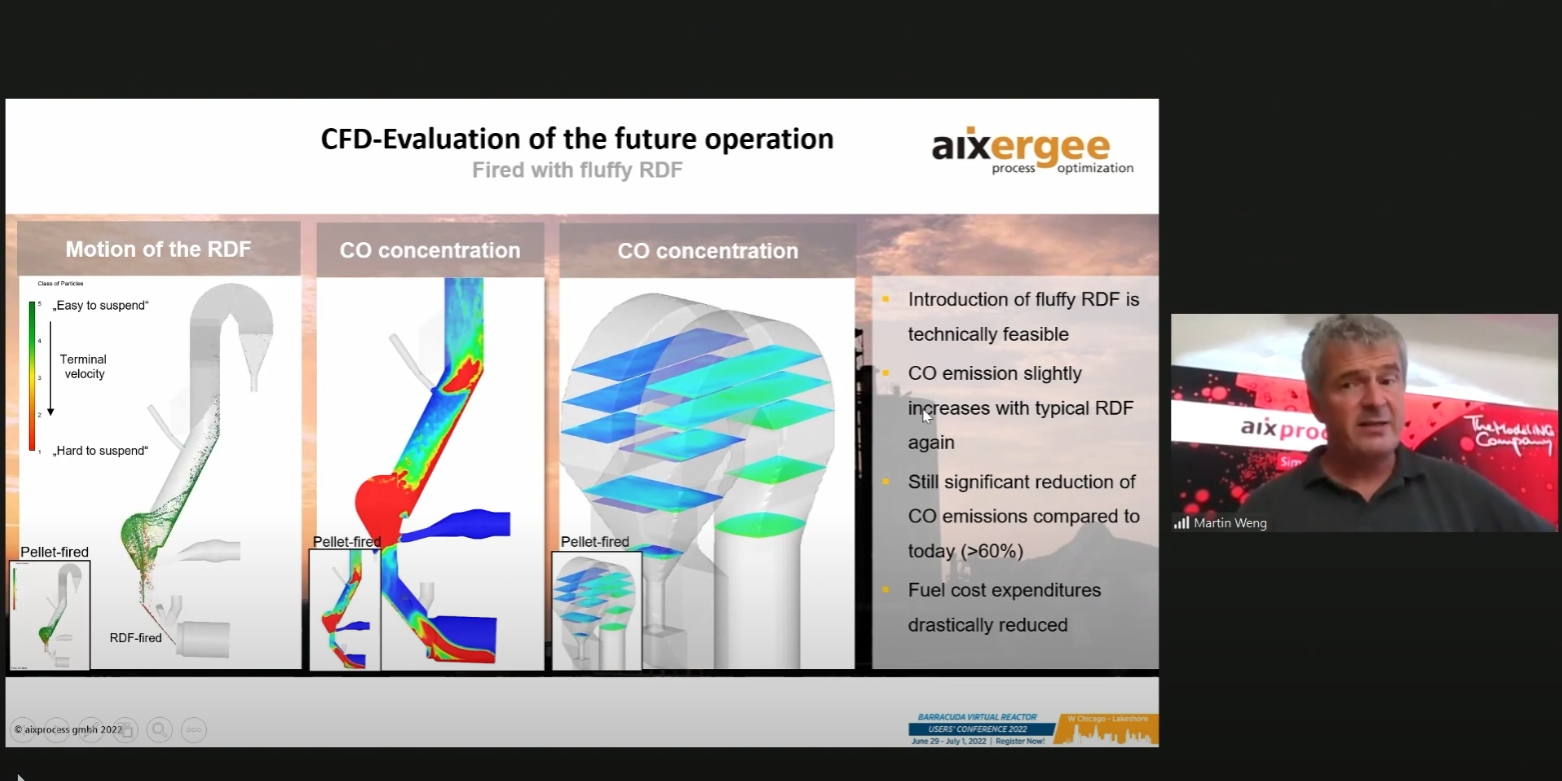

A German cement plant was planning to optimize their production in terms of increasing the thermal substitution rate to 100% in the calciner, aiming at entirely coal-free operation. At the same time, some CO limit exception issues should be overcome. After analyzing fuel kinematics and combustion behavior, a modification concept was developed resulting in an innovative design of a specific combustion chamber without any reference or experience from other installations. The plant decided to use advanced simulation as an engineering base in order to de-risk the modification for the next revision. In a few weeks’ time, the design was analyzed and optimized in a series of multi-physics Barracuda Virtual Reactor simulations with simultaneous computation of dense particle flow, multi-fuel combustion and calcination reactions. After installation, the process showed the expected optimized operation with 70-80% CO reduction and 100% calciner TSR. In addition, some refractory hot spots could be eliminated resulting in savings of maintenance costs. Fuel cost could be reduced by 2.4 € / t clinker (without consideration of CO2 costs), return on invest for full modification was less than 6 months.

About the Speaker

Martin combines engineering skills and entrepreneurship: while working as an assistant scientist in process engineering at the RWTH Aachen (Aachen University of Technology) from 1996 – 2002, he founded aixprocess company for technical consulting and simulation services in 2001. In the following years, he established aixprocess as one of the leading simulation providers in Germany, building up a team of more than 20 highly qualified experts for modeling and simulation. Comprehensive engineering with a focus on cyclone, fluidized bed and high temperature process technology complement the portfolio as a process optimisation company with international customers throughout the process industry. In 2015, Martin initiated the development of aixProM software platform for real-time Big Data Analytics and online process digitalisation – joining well-established engineering models with Big Data statistics and AI.