|

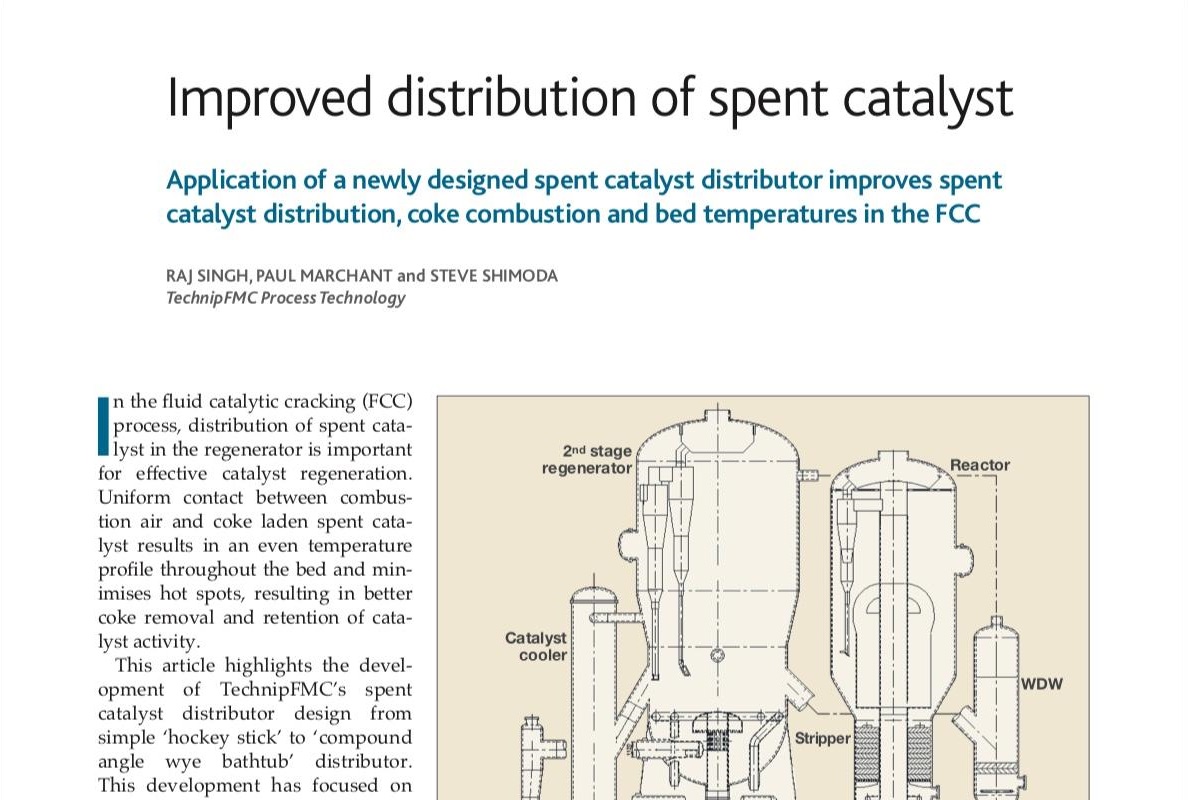

In TechnipFMC‘s recent article, Improved Distribution of Spent Catalyst, the development of TechnipFMC’s spent catalyst distributor design from simple ‘hockey stick’ to ‘compound angle wye bathtub’ distributor is highlighted. This development has focused on improving spent catalyst distribution in the FCC regenerator bed with the process benefit of uniform coke combustion and bed temperatures. CPFD Software’s proprietary software, Barracuda Virtual Reactor, was used to guide the development of TechnipFMC’s latest design and confirm improved catalyst distribution. Data from commercial FCC units showing a close to even temperature profile in the regenerator with their latest spent catalyst distributor confirms the design expectation.

Congratulations to Raj Singh, Paul Marchant and Steve Shimoda with TechnipFMC Process Technology on their excellent work. We are proud that Virtual Reactor™ was able to support TechnipFMC’s continued innovation.

TechnipFMC

TechnipFMC is known in the refining and petrochemical industry for its FCC technology. They work toward the vision of enhancing the performance of the world’s energy industry with their proprietary technologies, production systems, and integrated expertise and comprehensive solutions.