About This Video

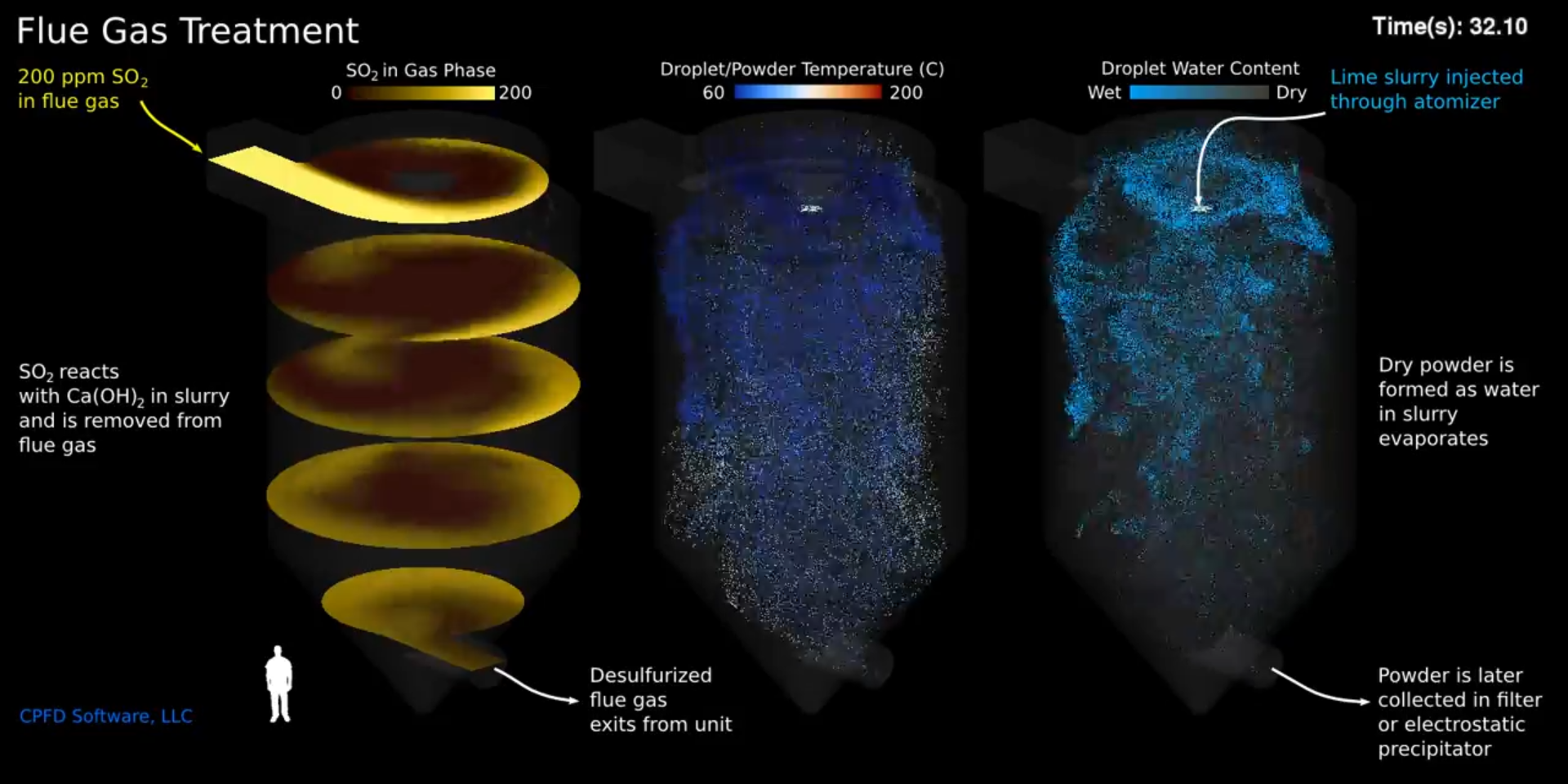

This video shows transient computational fluid dynamics model results for an industrial dry flue gas desulfurization system. A hot gas stream containing 200 PPM SO2 enters and encounters an atomized lime slurry. The SO2 reacts with the calcium hydroxide to form calcium sulfide. The water evaporates leaving a dry powder containing the sulfur. Computational modeling was performed using several unique features of the Barracuda Virtual Reactor including local particle/droplet injection, multi-phase chemistry and evaporation/drying models. One can easily see the potential for using CFD for design optimization, since the reactions only occur in the aqueous phase of the slurry droplets, but ideally only dry particles remain upon exiting the system.

Download the paper here:

CPFD Modeling of Industrial-Scale Dry Flue Gas Desulfurization System

James Parker, Ken Williams, Paul Zhao, Scott Thibault