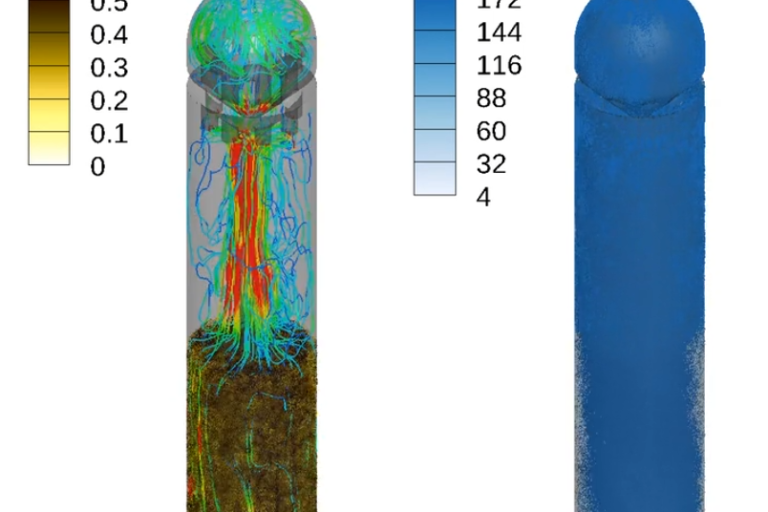

Ebullated Bed Three-Phase Simulation

This video demonstrates the discrete bubble modeling feature introduced in Barracuda Virtual Reactor 22.1. The simulation models an ebullated bed reactor with a fluidized bed of catalyst particles in liquid phase domain, with discrete gas bubbles injected.

Barracuda Virtual Reactor solutions for FCCU applications are accelerated by NVIDIA GPU and Multi-GPU technology.

Barracuda Virtual Reactor solutions for FCCU applications are accelerated by NVIDIA GPU and Multi-GPU technology.