FLSmidth is a global leader with nearly 140 years’ experience in the cement industry. Since their founder in 1882 discovered the technology behind the horizontal cement kiln, innovation has been at the core of FLSmidth’s culture. Today they are a leader in leveraging digitalization technologies to innovate sustainable and optimized equipment and processes with a minimal environmental footprint.

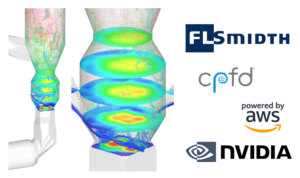

To achieve these goals FLSmidth utilizes Barracuda Virtual Reactor® from CPFD Software to design, optimize and scale their unique cement calcination technology. “Using Virtual Reactor™, we’ve explored a wider range of possibilities than we ever could have considered using physical testing for scaling up to industrial size. The AWS platform allowed us speed, scalability and flexibility in our simulations,” said Rüdiger Zollondz, Vice President of Innovation and R&D at FLSmidth. “The digitalisation technology enables us to optimise the energy efficiency and emissions of our cement technologies while also minimising our overall carbon footprint.”

While extremely powerful, such simulation technology is also very compute intensive and time consuming. According to Sam Zakrzewski, Fluid Dynamics Specialist, “we would regularly run simulations that take 1-2 weeks to complete for a single design analysis, so comparing five design alternatives would take 5-10 weeks on a fairly high end engineering workstation if we were to run them serially. Ideally, we would like to compare as many design iterations as we can virtually via physics based simulation methods before identifying and implementing the final design. To simulate multiple design scenarios simultaneously, we would need to invest in additional hardware, which will not be fully utilized all the time.”

Running Simulations On The AWS Cloud

Once the project scope was finalized, FLSmidth, CPFD Software and AWS teams worked together in identifying the appropriate AWS HPC services (Compute, Storage, Networking, Orchestration and Post-processing services). Amazon Elastic Compute Cloud (EC2) offers nearly 400 instances for virtually every business need across 24 Regions and 77 Availability Zones. For this particular workload, EC2 P3 instance with NVIDIA Tesla V100 GPUs was chosen since Virtual Reactor harnesses the commute capabilities of NVIDIA GPUs. By selecting p3.8xlarge instance, the simulations had access to four NVIDIA V100 GPUs. Switching to NVIDIA Tesla V100’s alone resulted in a nearly a 4x speed-up over FLSmidth’s legacy on premise compute capabilities and all in a familiar environment. At the time of writing, all parties are excited to try the newly-available P4d instance which includes NVIDIA Ampere A100 GPUs.

Using the AWS Parallel Cluster, FLSmidth was able to easily integrate other AWS HPC services such as FSX for Lustre, NICE DCV. Once the cluster was up and running, FLSmidth began running multiple cases concurrently. For a recent project, FLSmidth ran five simulations over a weekend, which only months prior would have taken over 40 days to complete sequentially using limited on premises capacity.

Vision For The Future

The road to a greener future is paved with cement and minerals. Growing populations need cement for housing and infrastructure, and FLSmidth is driving sustainable productivity under an initiative known as MissionZero. According to Thomas Schultz, CEO of FLSmidth, “With MissionZero, we accelerate the use of technology and knowledge to enable our customers to produce cement and process minerals with zero environmental impact.” Using Barracuda Virtual Reactor on NVIDIA GPUs powered by AWS, the world leaders in cement technology, advanced industrial fluid-particle simulations, GPU computing and cloud computing have come together to drive positive change.

From a computational perspective, this means that FLSmidth’s engineers have local access to Barracuda Virtual Reactor in their various global teams, but always on or compute critical activities are performed in the cloud, powered by AWS. CPFD’s on-demand licensing model, together with the virtually unlimited compute power of AWS, puts FLSmidth in control of their digitalization future.

Benefits Of AWS

- Reduces simulations project timeframes from months to days

- Virtually unlimited compute capacity

- On-demand access to the latest NVIDIA GPU technology

- Broader R&D exploration enabling aggressive environmental solutions

For More Information

About FLSmidth

FLSmidth delivers sustainable productivity to the global mining and cement industries. We deliver market-leading engineering, equipment and service solutions to our customers enabling them to improve performance, drive down costs and reduce environmental impact. With MissionZero, our 2030 ambition is to enable zero emission and zero waste (water, energy) in cement production and mining. Our operations span the globe and our 11,700 employees are present in more than 60 countries. In 2019, FLSmidth generated revenue of DKK 20,6 billion.

About NVIDIA

NVIDIA’s invention of the GPU sparked the PC gaming market. The company’s pioneering work in accelerated computing—a supercharged form of computing at the intersection of computer graphics, high performance computing and AI—is reshaping trillion-dollar industries, such as transportation, healthcare and manufacturing, and fueling the growth of many others.

About CPFD Software

CPFD Software has specialty expertise in fluid-particle systems and simulations. Our Barracuda Virtual Reactor software technology, provides particle-fluid dynamics simulation for engineering design and optimization of industrial fluidized systems and components. Virtual Reactor simulation solutions are provided worldwide via software licensing, simulation services, engineering consulting and technology transfer programs.