CPFD Software is pleased to announce the renewal of its software licensing agreement with Aurrenak & Loramendi Group, reaffirming their continued use of the Arena-Flow simulation software. The Aurrenak & Loramendi Group is a worldwide leader in delivering premium, integrated solutions for the foundry industry, recognized for its technological expertise and commitment to innovation.

Aurrenak & Loramendi Group: Integrated Solutions for the Future of Foundry

The Aurrenak & Loramendi Group is a strategic alliance that provides complete, high-value solutions to the global foundry industry. By combining Loramendi’s expertise in machinery and automation solutions with Aurrenak’s specialization in high-precision tooling and mould design, the group delivers fully integrated solutions for the production of iron, aluminium and steel castings.

With over 50 years of experience and a team of more than 400 professionals, the group has subsidiaries in seven countries worldwide, including a combined commercial and production site in Mexico, and commercial offices in China, India, Germany, United States, Kazakhstan and South Africa. This global presence positions the group as a trusted technology partner for leading automotive manufacturers such as Volkswagen Group, BMW, Daimler, General Motors, Renault-Nissan, Honda, Volvo, Scania, and Porsche, among others.

Loramendi, is a global reference in delivering complete solutions for core manufacturing processes and vertical moulding for foundry companies. The company is structured around three main business units: Core Making, Vertical Moulding, and Service, which includes retrofitting and technical support. Loramendi exports 95% of its production and is at the forefront of automation, digitalization, and sustainability in the foundry sector.

Aurrenak designs and manufactures moulds and tooling for the high-volume casting industry, both in iron and aluminium. The company is expert in High Pressure Die Casting, Gravity Die Casting, Low Pressure Die Casting & Iron Sand Casting (green sand & Sand Core Package technologies).

With facilities in Spain and Mexico, Aurrenak supports major OEMs and Tier 1 suppliers across the automotive and industrial sectors. As a cooperative, over 90% of its workforce are members, reinforcing its commitment to shared growth and collective success.

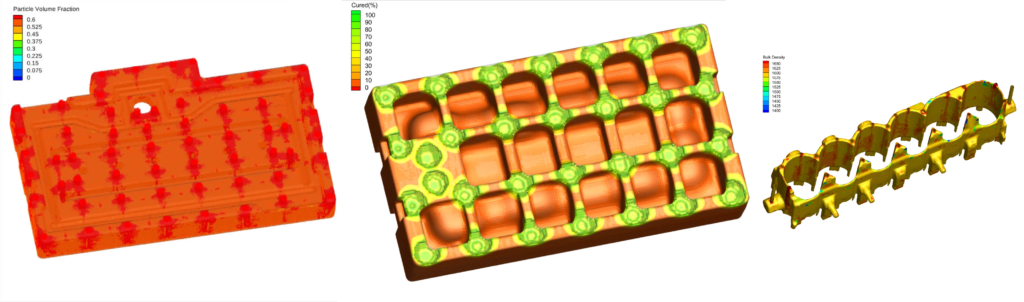

The strength of the group lies in the synergies between machinery and tooling, enabling a full approach that covers the complete development cycle— from concept design and prototype validation to process optimization and industrial deployment. Through advanced simulation tools like Arena-Flow and in-house testing capabilities, the group ensures that each machine–tooling system is precisely optimized for maximum performance, durability, and precision.

Looking ahead, the Aurrenak & Loramendi Group is leading strategic projects for the 2025–2028 cycle, with a focus on optimizing core shooting processes across multiple foundry technologies—a growing challenge due to the increasing complexity and diversity of sand cores. The integration of Arena-Flow plays a key role in this development, supporting simulation-driven design validation and enabling a seamless transition from digital models to real-world production environments.

In response to the ongoing transformation of the automotive industry—from combustion engines to hybrids & electric mobility—Aurrenak & Loramendi are aligning their technological capabilities and cooperative model to stay ahead of the future challenges and actively contribute to the sector’s evolution.

Bringing Digital Simulation into Industrial Reality

Unlike segmented partnerships, the Aurrenak & Loramendi Group integrates machinery, tooling and simulation within a unified structure, enabling complete control and validation of the entire process chain—from core box design and manufacturing to machine implementation and on-site performance optimization.

Unlike segmented partnerships, the Aurrenak & Loramendi Group integrates machinery, tooling and simulation within a unified structure, enabling complete control and validation of the entire process chain—from core box design and manufacturing to machine implementation and on-site performance optimization.

By combining digital simulation with real-world testing and in-house facilities, the group can ensure that Arena-Flow predictions correlate directly with actual machine behavior—bridging the gap between virtual models and industrial reality and taking a step further in digitalizing the core making process.

This approach is already being applied in projects for top-tier automotive manufacturers, where the simulation insights provided by Arena-Flow have translated into measurable gains in tooling durability, process stability, and core quality.

“Aurrenak has been using Arena-Flow simulation software for more than 15 years to ensure the proper performance of tooling in cold box, inorganic, and hot box technologies. This software enables us to control the quality of sand core filling and curing while minimizing tooling wear. The synergy between Aurrenak and Loramendi allows us to simulate the entire machine–tooling system behavior. In addition, our in-house testing capabilities let us correlate simulation results with real production outcomes—ensuring a fully validated manufacturing process before it reaches the customer,” explains Zuriñe Garitaonaindia, Foundry Process and Simulation Manager. “This ensures our clients receive a process that is optimized, tested and ready to deliver results.”

“It is exciting news for CPFD’s Arena-flow core blowing simulation software user community, that the Loramendi & Aurrenak group, a leading equipment supplier to the global foundry industry, is expanding their use of Arena-flow,” said Thomas Brandt, Manager, Foundry Products & Service at CPFD Software. “Loramendi & Aurrenak continue to serve as an industry leader, and we look forward to supporting them for years to come.”

About Aurrenak & Loramendi Group

Aurrenak & Loramendi, based in Vitoria-Gasteiz (Spain) and part of the MONDRAGON Corporation, form a strategic alliance that delivers integrated solutions for the foundry industry. Combining advanced machinery, automation solutions, and precision tooling, the group brings over 50 years of experience, a strong innovation culture, and a global presence. Trusted by leading automotive manufacturers, Aurrenak & Loramendi export 95% of their production and are key partners in the transition towards next-generation casting technologies.

Together, Aurrenak & Loramendi are driving the future of the foundry industry through innovation, global service, and a shared vision of integrated excellence.

About CPFD Software

CPFD Software is advancing multiphase simulation and technology. Our foundry project, Arena-flow, is specialty software for simulation of sand cores and molds. We assist OEMs, foundries, and tooling suppliers worldwide in minimizing scrap, cycle times, consumable usage, energy costs, carbon footprint, and new tooling startup costs, ultimately enabling them to commission or convert core-making processes with confidence while producing tooling and cores that are right the first time.

Learn more about Arena-flow here.