Application Model Overview

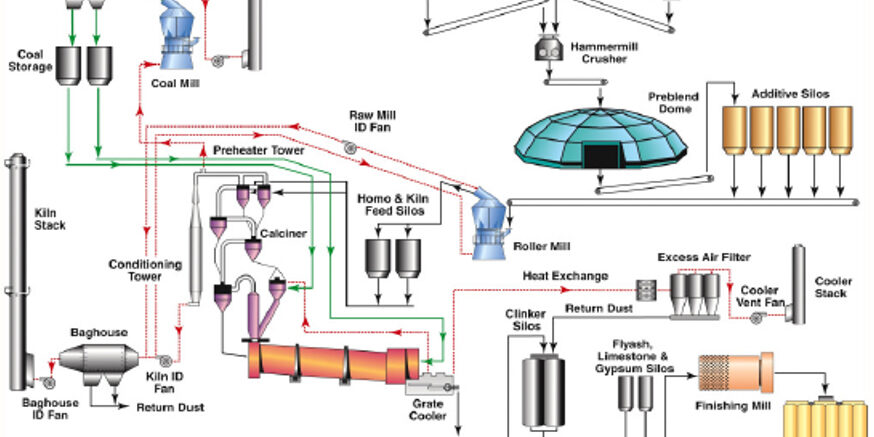

In cement production, preheating and cooling steps play a vital role in optimizing energy use and ensuring the longevity of equipment. A key component in this process is the conditioning tower, which cools hot exhaust gases from the Calciner and kiln before they enter downstream systems.

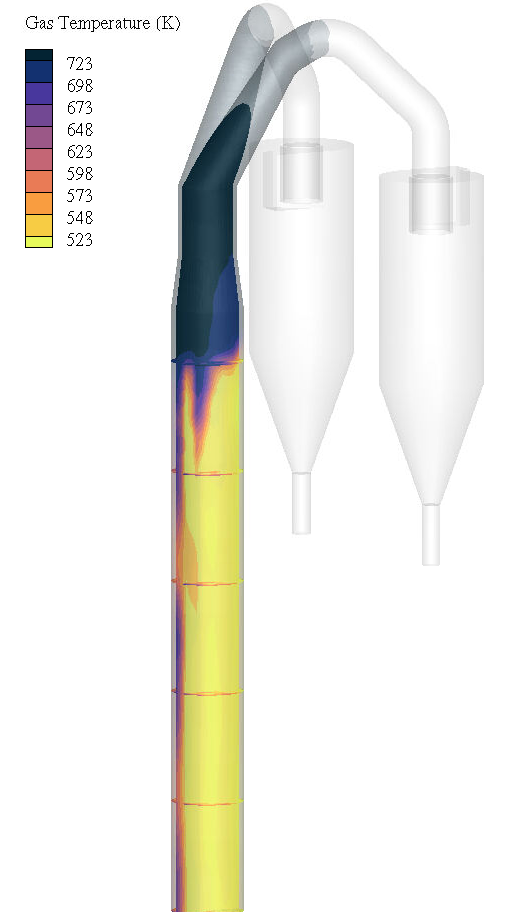

This application model uses Barracuda Virtual Reactor to simulate gas cooling in a cement plant’s conditioning tower. Hot gas and raw material from the preheater are fed into cyclones, separating particles, while unseparated fines enter the conditioning tower. Water droplets are injected via nozzles, cooling the gas through evaporation.

With its evaporative cooling capabilities, Barracuda models how variables like injection rates, nozzle placement, and airflow impact cooling efficiency. By visualizing gas temperature, water droplet evaporation, and heat transfer, Barracuda helps optimize cooling while preventing equipment damage due to excessive heat.

This simulation demonstrates Barracuda’s ability to analyze complex fluid-particle interactions, making it an essential tool for improving energy efficiency in industrial-scale processes like cement manufacturing.