Application Model Overview

Circulating fluidized bed (CFB) combustors provide a robust and flexible pathway for coal- and waste-derived power generation while operating at lower temperatures (≈800–900 °C) than pulverized-coal boilers. This lower-temperature, solids-rich environment promotes strong gas–solid mixing, long residence times, and effective burnout of challenging fuels—including high-ash coals, petcoke, biomass, and waste-derived fuels—while also helping reduce pollutant formation. In a typical CFB, solids (primarily ash and sorbent) circulate continuously through the riser and cyclones, enabling uniform temperatures, efficient heat transfer, and opportunities for in-furnace emissions control.

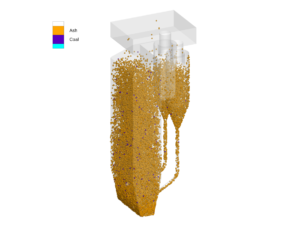

This application model uses Barracuda Virtual Reactor to simulate an industrial-scale CFB combustor based on a 110 MW unit described in the open literature. The model includes realistic furnace geometry with multiple coal injectors, staged secondary air, dual cyclones, and return diplegs, capturing the core hydrodynamics of solids circulation and fuel residence behavior. The simulation is configured as a compressible, reacting, thermal system with temperature-dependent properties and wall heat-loss treatment, providing a practical starting point for full-scale CFB combustion analyses.

A comprehensive reaction scheme combines rapid volatile release, gas-phase oxidation and reforming, and heterogeneous char reactions, enabling prediction of both major products (CO₂, H₂O) and key pollutants at trace levels (e.g., NO and SO₂). The model illustrates how air staging influences oxygen availability in the dense zone and supports NOₓ mitigation pathways, while sorbent-based capture chemistry is represented to reflect in-furnace sulfur control concepts. Results demonstrate realistic qualitative trends in solids circulation, fast devolatilization, progressive char burnout, and spatial distributions of O₂ depletion, CO₂ formation, NO behavior, and temperature throughout the riser.

This application model serves as a reusable reference for engineers studying industrial CFB hydrodynamics, combustion chemistry, pollutant formation, air-staging strategies, and fuel flexibility, and provides a foundation for extending Barracuda simulations to related systems such as CFB boilers, waste co-firing, and sorbent-based emissions control.