Application Model Overview

Hydraulic fracturing relies on proppants to hold newly formed fractures open and sustain hydrocarbon flow. Achieving an even proppant distribution across the fracture network is critical: heel-skewed packing can choke flow near the wellbore while starving the toe. This application model uses Barracuda Virtual Reactor to simulate proppant transport in a slickwater carrier, capturing the coupled particle–fluid behavior that governs fluidization, sedimentation, dune formation, and long-term bed stability.

The model represents a lab-scale mock fracture channel (≈48″ × 12″ × 0.5″) with three inlets and two outlets, operated under incompressible conditions. A 40/70 mesh sand slurry is injected at a combined 6 gpm to study how particle size distribution (PSD) and inlet configuration influence deposition. Slickwater’s shear-thinning behavior is accounted for via a user-defined, power-law–based drag (Chhabra-style modification of a standard drag correlation), enabling realistic prediction of proppant momentum exchange without adding reaction or heat-transfer complexity. The project file ships pre-configured with geometry, materials, boundary conditions, and post-processing views.

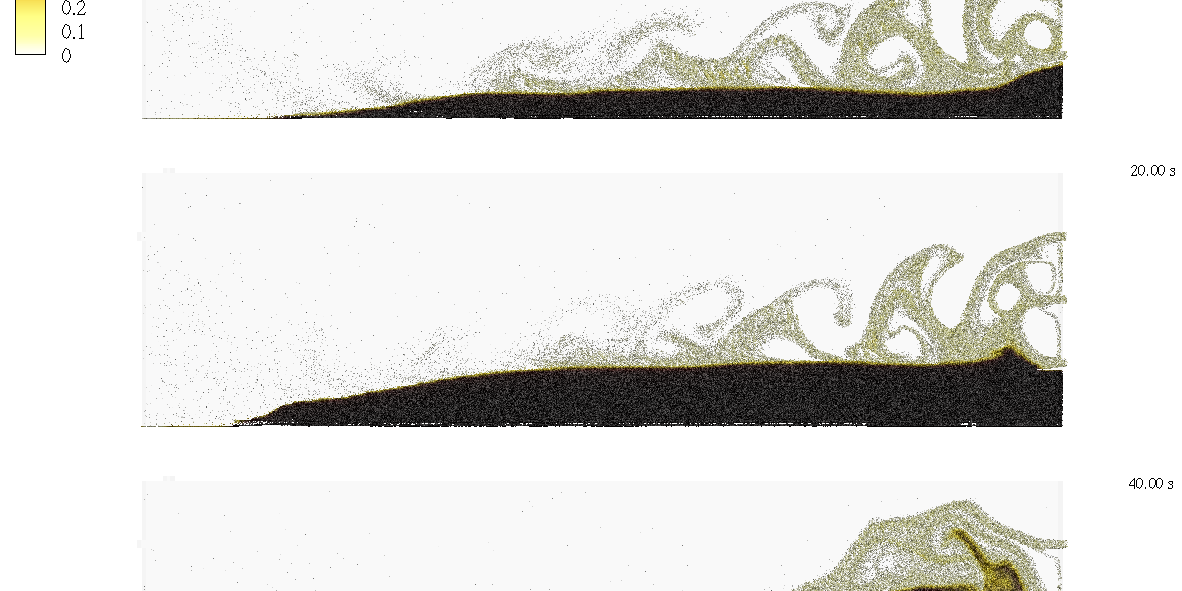

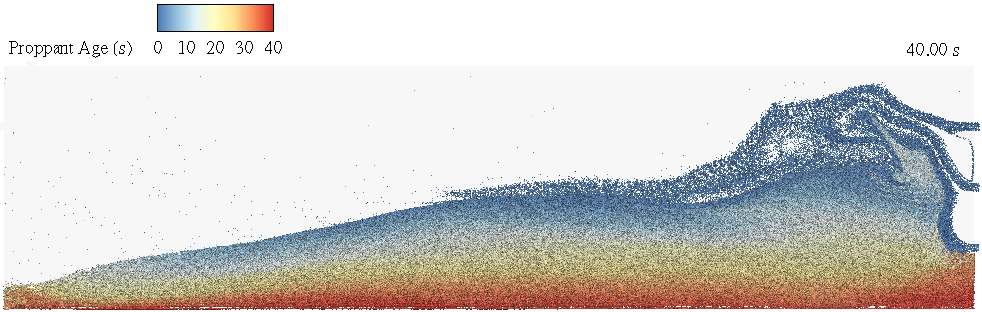

Simulation results reproduce key transport phenomena observed experimentally: early fluidization near the inlets transitions to sedimentation downstream, yielding a growing dune and a heel-skewed bed profile over time. Layering by proppant age highlights how newly injected particles ride the fluidized layer while older particles consolidate the bed. PSD sensitivity studies (within the 40/70 range) show the trade-off between reach (smaller particles) and heel accumulation (larger particles), aligning with reported trends and providing a practical basis to tune proppant sizing and pumping strategy. This digital twin of a fracture channel offers engineers a fast, validated environment to evaluate injection sequencing, PSD selection, and operating conditions to improve fracture coverage and production outcomes.