Application Model Overview

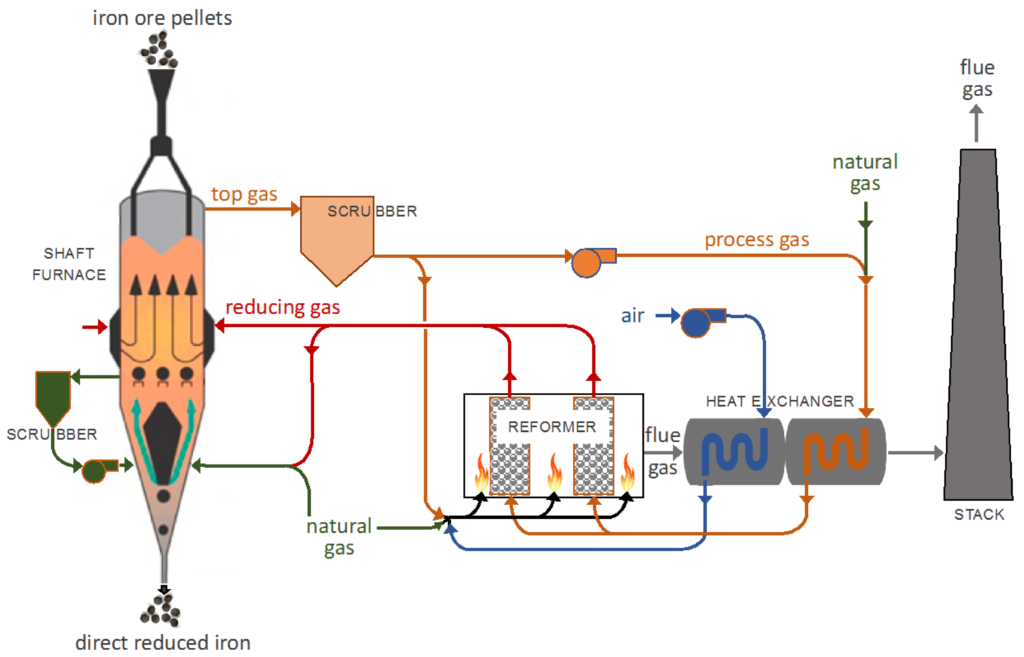

Direct reduced iron (DRI) processes offer a promising pathway for decarbonizing steel production, enabling significant reductions in CO₂ emissions compared to traditional blast furnace methods. In the MIDREX DRI process, iron ore pellets are reduced by a hydrogen- and carbon monoxide-rich gas in a vertical shaft furnace, producing solid iron without the need for coke-based reduction.

This application model uses Barracuda Virtual Reactor to simulate the thermal and chemical behavior of a full-scale DRI shaft furnace based on operating data from a commercial plant in Quebec, Canada. The model captures key process zones—including cooling, reducing, and transition regions—using a moving bed framework with compressible flow, volumetric and discrete reaction chemistry, and user-defined reaction kinetics.

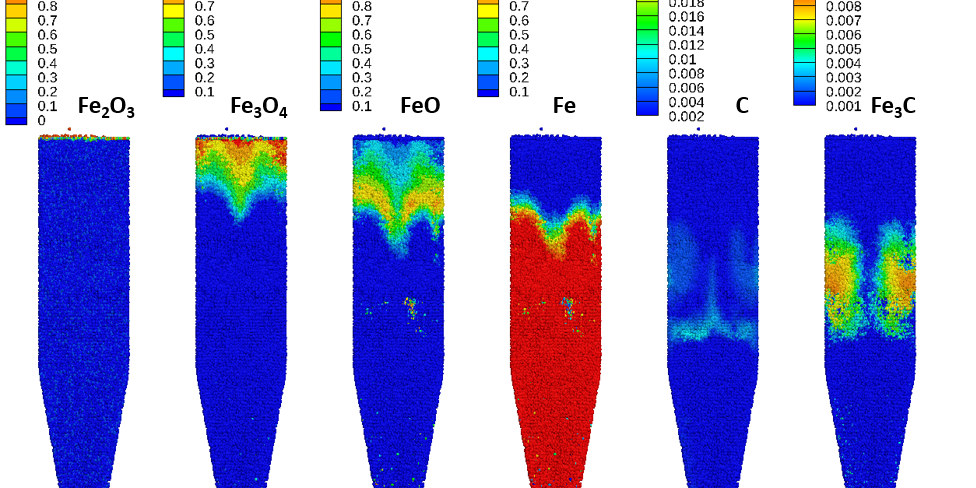

Iron ore reduction is modeled via a three-step unreacted shrinking core model (UCSM), tracking the transformation of hematite (Fe₂O₃) to metallic iron (Fe). The simulation also incorporates gas-phase reforming and water-gas shift reactions, carburization, and iron carbide formation. Model predictions, including gas species profiles and solids conversion behavior, are benchmarked against published REDUCTOR model results and MIDREX plant data, showing strong agreement.

This digital twin enables detailed analysis of gas-solid interactions, reactor temperature profiles, and reaction kinetics, supporting optimization of low-carbon ironmaking technologies and accelerating the transition to hydrogen-based steel production.