CPFD Software and DAL Teknik Makina have entered into a multi-year software licensing contract for CPFD’s Barracuda Virtual Reactor® Software. DAL Teknik Makina, a member of the DAL Group, uses Virtual Reactor™ to design, scale and trouble-shoot cement technology equipment and processes resulting in multiple benefits to their customers including:

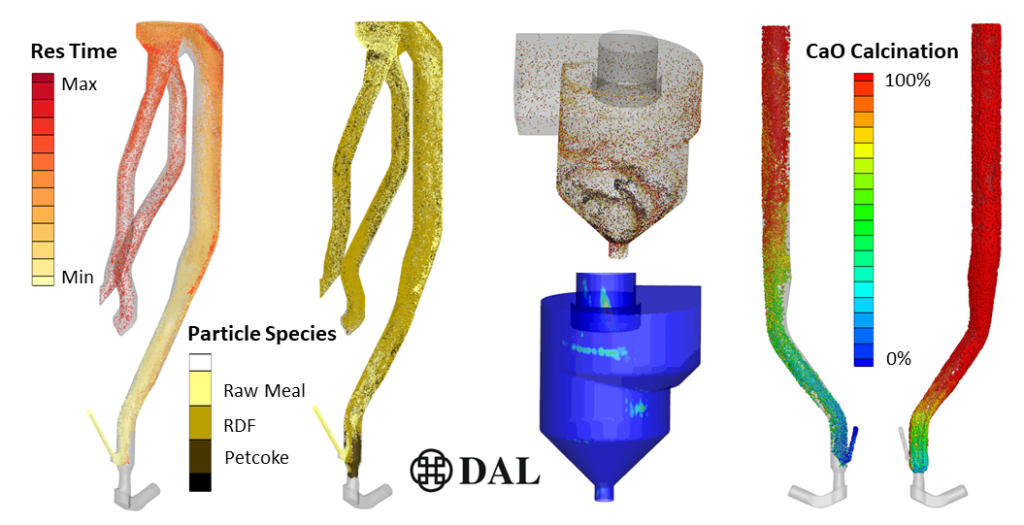

Alternative Fuel Flexibility The combustion of alternative fuel (AF) is one way cement plants can utilize the increasing quantity of global waste, supporting environmental sustainability while reducing primary fuel consumption. Cement plants are ideally suited to utilize the energy from AF due to their high operating temperatures. For this reason the realizable modeling of AF is critical. Barracuda Virtual Reactor enables accurate modeling of the complexities of multiple particle species including AF particles and their combustion behavior.

Lower NOx, SOx and Carbon Emissions Barracuda Virtual Reactor’s efficient calculations of chemical compositions of particles and gases and the resulting multiphase reactions helps in lowering NOx, SOx and carbon emissions. As a result, Dal Teknik Makina’s customers experience optimized calciner operations resulting in lower-emission plants with a minimized carbon footprint.

Higher Energy Efficiency Heat and electricity consumption is a primary factor affecting overall energy efficiency. Dal Teknik Makina’s state of the art cyclone and riser duct designs, verified through Virtual Reactor simulations, maximize heat transfer and minimize pressure drop across the process resulting in minimized energy consumption.

Improved Erosion Resistance and Reliability Material wear due to chemical attacks and particle impacts can result in material failure, especially in the lower stages of the preheater. Thus, predicting erosion-critical areas are of the utmost importance to ensure overall reliability. Barracuda Virtual Reactor computes the particle-wall interactions and summarizes the erosion potential through an industrially verified erosion model. Dal Teknik Makina utilizes this model in its dip tube designs to minimize erosion via virtual testing and informed material selection.

“The Dal Engineering Group is continually seeking to enhance our technology and resulting value to our clients,” said Firat Aslan, Head of Technology Department at Dal Teknik Makina. “Our expanded use of Barracuda Virtual Reactor will directly benefit our customers for years to come.”

CPFD Software is pleased to continue supporting the global cement industry. Contact us to learn more about Barracuda Virtual Reactor or contact DAL Tecknik Makina for more about thir cement technology and offerings.

About DAL Group

Dal Engineering Group (DEG) is providing turnkey projects via its group companies and giving engineering services to different industrial sectors in Turkey, and all around the world. DEG provides solutions, including procurement of the equipment & machinery, engineering, construction, automation, electrical works, and raw materials, for cement, mineral, energy, environment and recycling industries. DEG consists of the following companies:

- Dal Teknik Makina

- Dal Electric Motor & Drives

- Dal Electric & Automation

- FONS Technology International

- Dal Machinery and Design

- Dal Renewal Energy

About CPFD, LLC

CPFD Software has specialty expertise in fluid-particle systems and simulations. Our Barracuda Virtual Reactor software technology, provides particle-fluid dynamics simulation for engineering design and optimization of industrial fluidized systems and components. Virtual Reactor simulation solutions are provided worldwide via software licensing, simulation services, engineering consulting and technology transfer programs.