Peter Blaser, CPFD Software’s Vice President of Engineering Services, will present a paper titled “Improving FCC Economics Through Computational Particle Fluid Dynamics Simulation” at the American Fuel & Petrochemical Manufacturers (AFPM) Annual Meeting held at the Marriott Rivercenter in San Antonio, March 19-21, 2017.

The FCC unit has a long history of upgrading low valued feed stocks into much higher valued LPG olefins and motor fuels. Potential for increasing profitability through modification of the configuration or design of FCCU components is often limited due to challenges in diagnosing the root causes of under-performance and the risk of possible negative impacts of implementing changes on operational reliability. Gains obtained via modifications to a stable but sub-optimal process can be quickly erased if unforeseen, adverse effects are experienced, particularly if the changes result in an unplanned shutdown. The result is a strong preference for the status quo over uncertainty, due to the lack of means to test proposed improvements prior to implementation.

The FCC unit has a long history of upgrading low valued feed stocks into much higher valued LPG olefins and motor fuels. Potential for increasing profitability through modification of the configuration or design of FCCU components is often limited due to challenges in diagnosing the root causes of under-performance and the risk of possible negative impacts of implementing changes on operational reliability. Gains obtained via modifications to a stable but sub-optimal process can be quickly erased if unforeseen, adverse effects are experienced, particularly if the changes result in an unplanned shutdown. The result is a strong preference for the status quo over uncertainty, due to the lack of means to test proposed improvements prior to implementation.

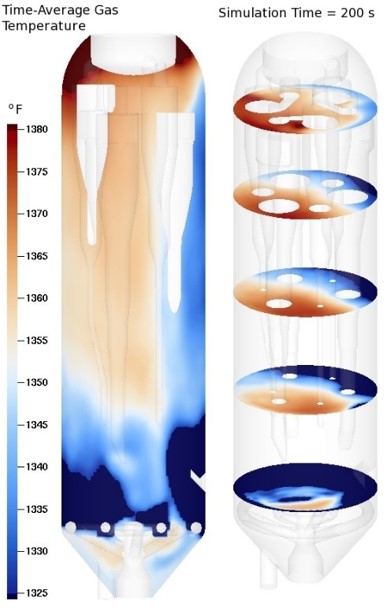

In recent years computational particle fluid dynamics engineering simulation technology has emerged as a powerful tool enabling refiners to “look inside” their FCCU and test the effect of proposed changes to equipment and process design. Simulation is being used to address issues such as erosion, catalyst losses, afterburn and emissions by identifying the root causes of operational problems and the effect of potential solutions.

This paper describes many additional structural issues which are endemic to the FCC operation resulting in limitations in operational flexibility with subsequent negative impact on economics. These issues include items such as incomplete combustion of spent catalyst within the regenerator commonly referred to as the “salt and pepper” appearance of regenerated catalyst, erosion of reactor or regenerator hardware leading to unscheduled shutdowns or reduced cycle length, and poor aeration at the inlets of regenerated catalyst hoppers and along the length of the standpipes leading to poor fluidization and reduced catalyst circulation rates. Each of the above conditions results in limited operational flexibility with either direct or indirect negative impacts on profitability

Please join us on on Tuesday, March 21 at 3:00 PM for the presentation, or contact us in advance to schedule an in-person meeting. To learn more about using Barracuda Virtual Reactor for FCC applications, visit our FCC Resources page.

Full Paper Now Available for Download

About The AFPM Annual Meeting

The Annual Meeting is the world’s premier refining meeting, assembling key executives, decision-makers, and technical experts from refining businesses, technology providers, contracting and consulting firms, and equipment manufacturers around the world. The general session features high profile speakers who will address current issues of importance to the industry. Leading industry experts will share valuable insights on major issues, including energy and environmental initiatives and the latest technical developments impacting the refining and petrochemical industry communities. Breakout sessions will have over 70 paper presentations which address legislative and regulatory issues; strategic issues; supply and demand projections; proven practices in operations, safety, reliability, and capital projects; and petroleum refining technologies such as FCC, hydroprocessing, and gasoline processes. Almost half of the presentations will be just as relevant to petrochemicals operations as they are to petroleum refining. For more information visit www.afpm.org.

Peter Blaser, CPFD Software’s Vice President of Engineering Services, will present a paper titled “Improving FCC Economics Through Computational Particle Fluid Dynamics Simulation” at the American Fuel & Petrochemical Manufacturers (AFPM) Annual Meeting held at the Marriott Rivercenter in San Antonio, March 19-21, 2017.

Full Paper Now Available for Download